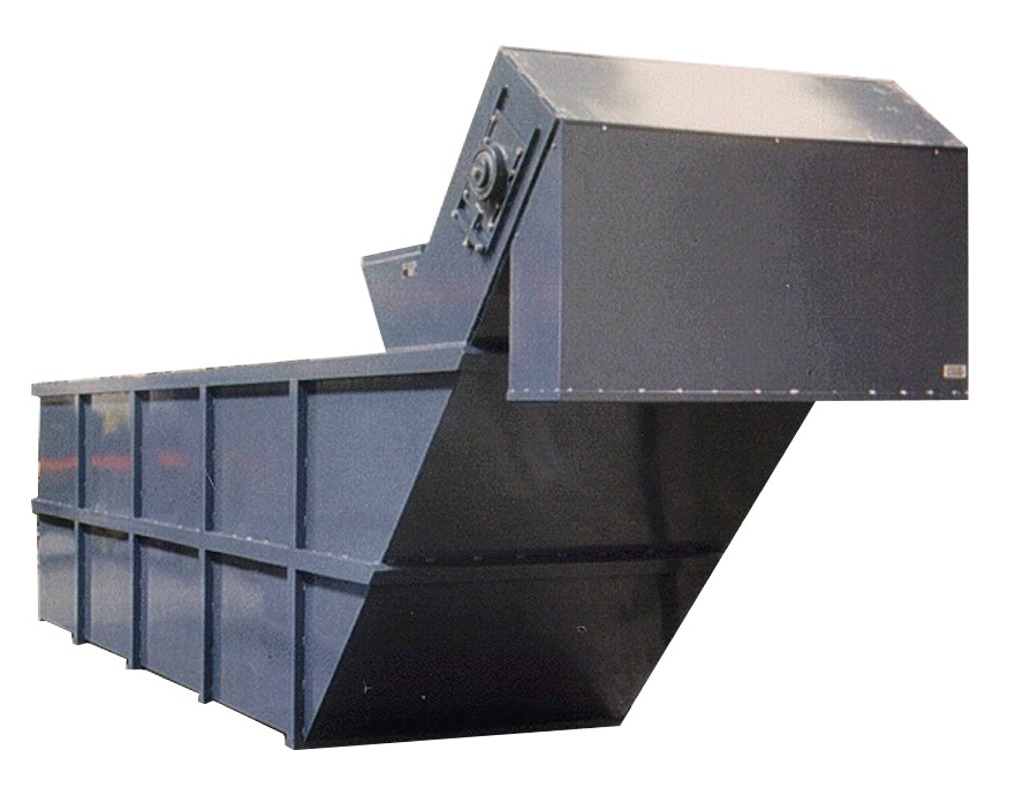

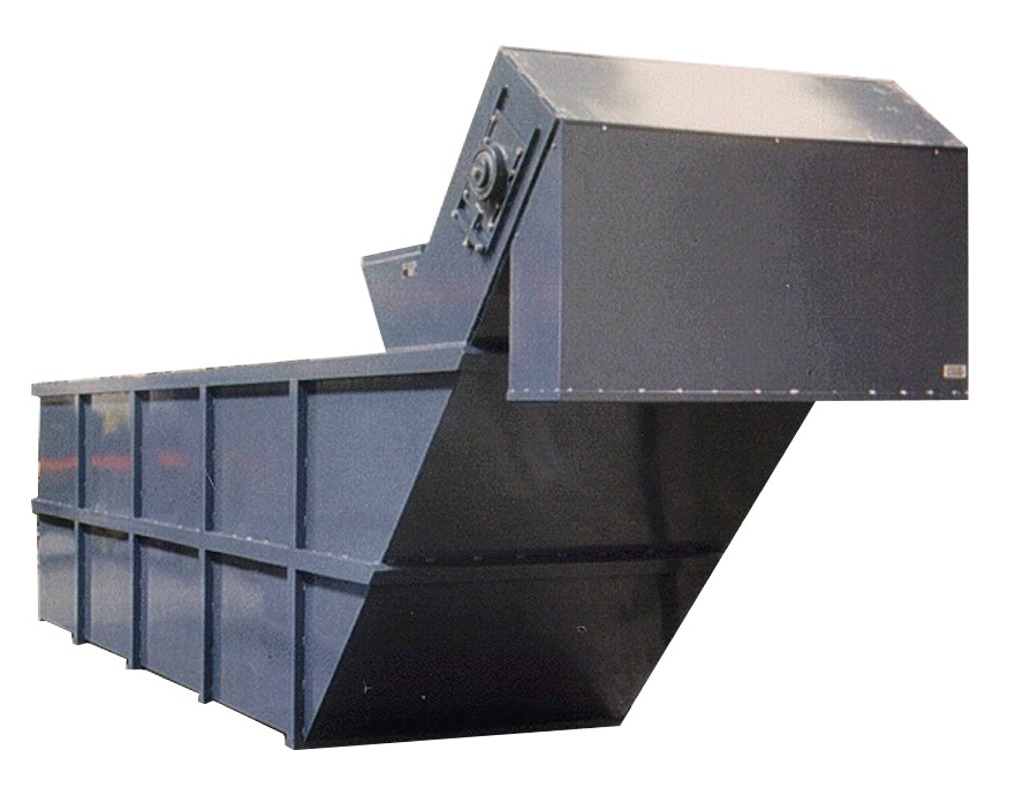

Sedimentation Container

Complete sedimentation container available in high-grade steel!

For more information please contact us:

Application

Application areas

Features

Subject to change!

Complete sedimentation container available in high-grade steel!

For more information please contact us:

Subject to change!